Most wastewater applications require chemical pretreatment to break the emulsions caused by chemical cleaners/surfactants/sanitizers or mechanical mixing. Breaking the emulsion will improve TSS, FOG, and BOD removal efficiencies from the waste stream.

Ellis offers two different technologies where the chemicals can react with the wastewater to provide chemical demulsification which allows the pollutants to chemically separate from the water. Ellis offers two solutions that provide the contact time and the mixing energy that allows treatment chemicals to react with the wastewater. These include Chemical Reaction Tanks (CRT) and Serpentine Mixing System (SMS).

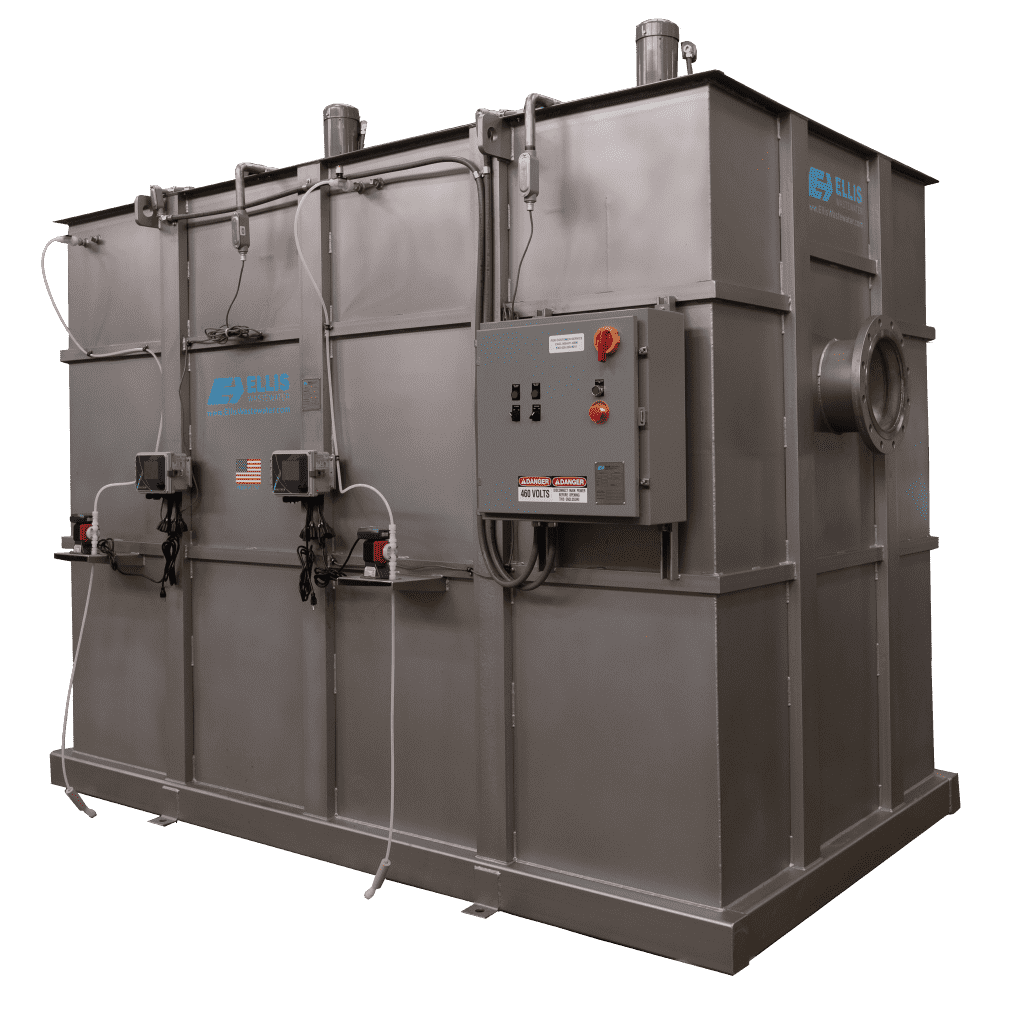

CHEMICAL REACTION TANKS, PH CONDITIONING AND SERPENTINE MIXING SYSTEM

These chemical reaction systems are designed to work with your chemical treatment program. Chemical Reaction Tanks come in various sizes (diameter, length, width, height, flat or cone bottom) in carbon steel and stainless steel. Included with mechanical mixing using impeller agitation to provide mixing energy.

HOW CHEMICAL REACTION SYSTEMS WORK

Wastewater is pumped into the chemical reaction tank. Most tanks are designed with two chambers and others may have two to four chambers based on the customer’s chemical treatment program.

In most two-chamber reaction tanks, the coagulant, pH adjustment, and coagulant aid chemicals are added into the first chamber and react for a five-minute time period. Mechanical action is provided using a mixer and with an impellor to blend the chemicals with the wastewater. In the second chamber, flocculant is added to the coagulated wastewater to provide a chemical reaction for a ten-minute period. This mixing energy is reduced so the flocculated particles do not sheer. A mechanical mixer with VFD controls and an impeller are used. The wastewater then gravity flows into the DAF or the IPC.

STANDARD CHEMICAL REACTION TANK

- Carbon Steel Construction with external and internal protective coatings.

- Mechanical Mixers

- Level Controls

- Tank Drains

CHEMICAL REACTION TANK OPTIONS

- Stainless Steel Construction

- Expandable Chambers from two to four or more.

- Walkways, Ladders, or Stairs.

- pH Monitoring and Control Systems

- Chemical Metering pumps

- Chemical Solution/Slurry Tanks

SERPENTINE MIXING SYSTEMS (SMS)

Serpentine Mixing Systems are engineered in various sizes and are constructed of stainless steel or PVC piping. No outside mixing energy is required. Reaction energy is provided by the influent pump impellor, velocity, and the turbulence caused by bends and turns of the serpentine piping.

The SMS is often used in applications where space is limited and can be placed along a wall or up against the equipment. The SMS is equipped with chemical injection points as well as sampling points to allow the operator to make the necessary chemical feed adjustments to optimize the chemical reaction.

The Serpentine Mixing Systems are constructed from PVC or Stainless Steel piping with no internal parts. Therefore, the SMS operates clog-free. This can be very important in industries that may have large solids or other debris in the wastewater.

HOW IT WORKS

The wastewater is pumped into the SMS using a high-velocity pump. Chemicals such as a coagulant or coagulant aid are injected as soon as the wastewater enters the SMS. Most of the mixing action is achieved in the turns and piping constrictions and expansions. Flocculant is added after the coagulant has mixed with the wastewater. The SMS piping is constructed with two different sizes to improve performance over a wider range of flows. The larger of the two pipes is used in the straight pipe runs to provide gentle mixing so as not to shear the floc particles and increase the hydraulic retention time. The wastewater will exit the SMS and flow into the separation technology such as a DAF or IPC. An inline pH meter can be installed in the SMS if pH neutralizing chemicals are required for chemical reaction or effluent compliance.

STANDARD SEPENTINE MIXING SYSTEM

- PVC Construction

- Four Chemical Injection and Sampling Ports

- Carbon Steel Serpentine Pipe Support Rack

SERPENTING MIXING SYSTEM OPTIONS

- Stainless Steel Construction

- Additional Chemical Injection and Sampling Port

- Stainless Steel Serpentine Pipe Support Rack

- pH Monitoring and Control Systems

- Chemical Metering pumps

- Chemical Solution/Slurry Tanks

Your Ellis Sales representative will assist you in selecting the correct materials for the construction and application of the chemical reaction system.

ENJOY THE BENEFITS OF CHEMICAL REACTION SYSTEMS

If you choose to go for one of the two chemical reaction systems offered by Ellis Corporation, you will get the many benefits that come with choosing chemical reactions over organic. The main benefit recognized with chemical reaction systems is their efficiency. These systems are known for their ability to speed up the process of breaking emulsions. For more information on our chemical systems, or to purchase any of our equipment, contact us! We are happy to answer any questions you may have. Contact Ellis Corporation today to get started with our services!