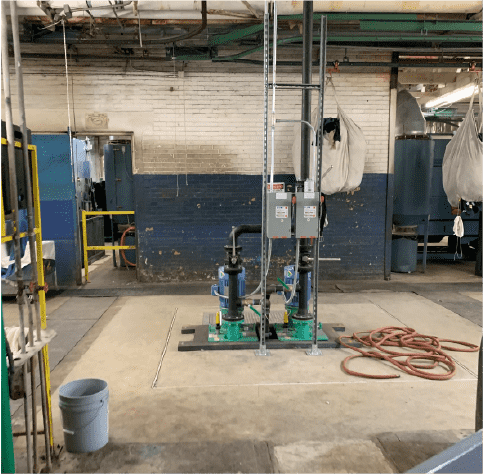

Sometimes you have big compliance goals but don’t have the space required for a large-scale system. Designing high-performance systems for those tight areas is something that Ellis can deliver. In many applications, there is a lack of floor space to install a full wastewater treatment system on the ground floor. Taking some of that equipment and placing it overhead allows floor space for the larger pieces of equipment while putting ancillary equipment on a platform. Manufacturing platforms, connecting walkways and stairways to keep equipment operating above the ground is part of our scope to make it fit.

Out of Room

When you can’t go up and there is no room in the building what do you do? Containerize the system. Buildings can become land-locked and space becomes limited but meeting compliance does not stop. Designing and installing compact systems is what Ellis can deliver.

Ellis has designed and installed systems inside shipping containers. These containers are compact and can be stacked if more space is required. Containers come equipped with heat or air conditioning, full electrical power with control panels, and running hot and cold water.

Ellis has designed and installed systems inside shipping containers. These containers are compact and can be stacked if more space is required. Containers come equipped with heat or air conditioning, full electrical power with control panels, and running hot and cold water.

Flocculators are used to chemically treat the wastewater before addition into a DAF.

A complete system including Dissolved Air Flotation (DAF) units, Oil Water Separators (OWS)

and Emulsion Breakers and small Inclined Plate Clarifiers can be added to containers to bring

the wastewater into compliance.

Nice and Compact

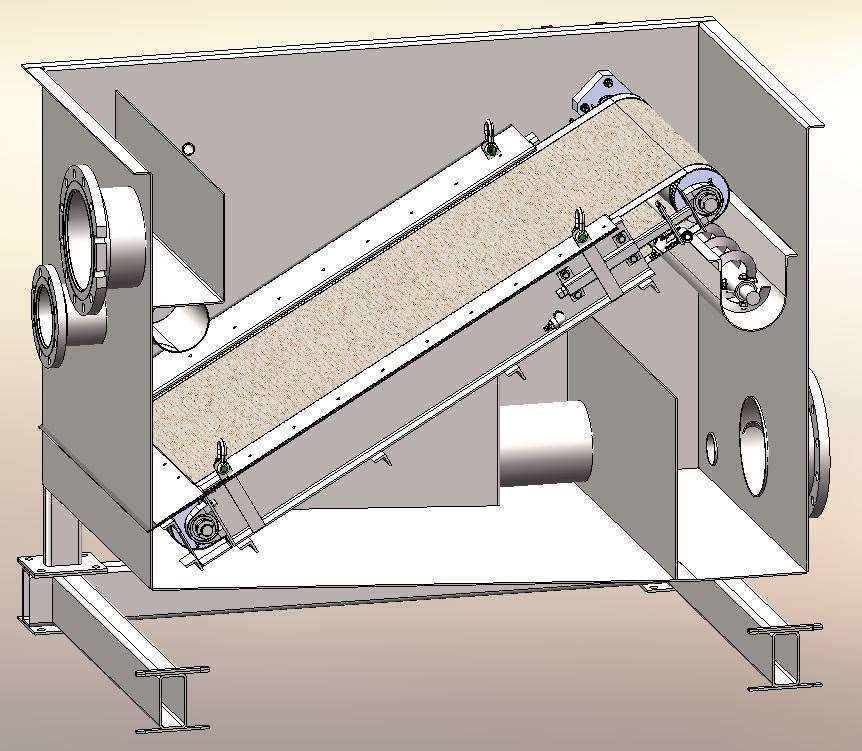

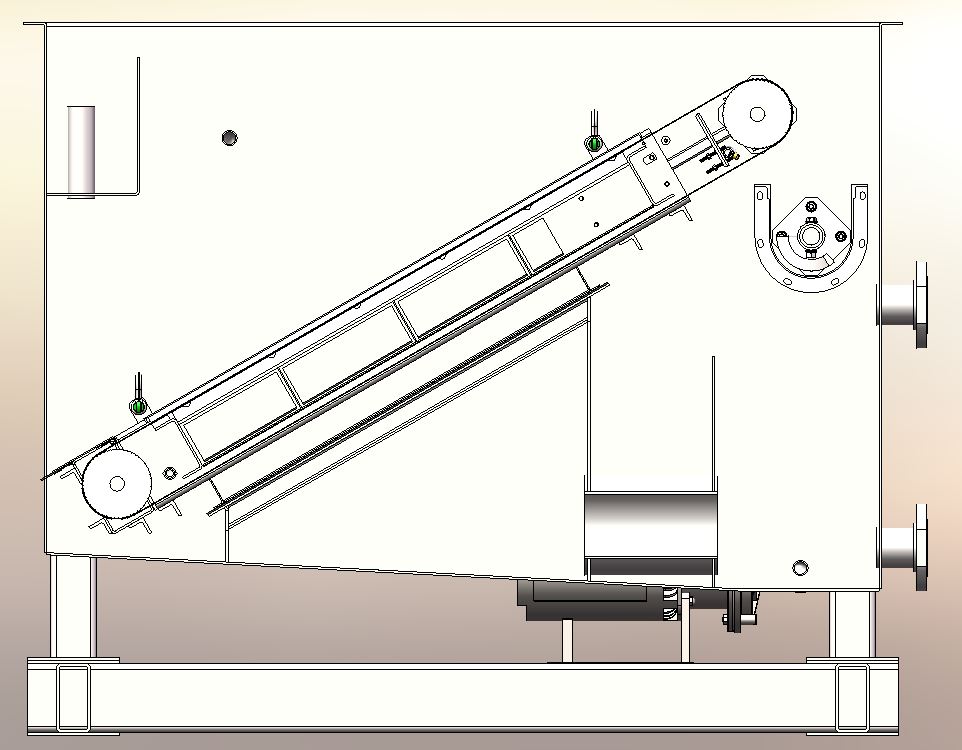

Ellis Corporation has engineered a filter belt system that has been able to help businesses such

as industrial laundries get into compliance with Fats, Oils, and Grease (FOG) or Hexane

Extractable Material (HEM) discharge limitations. The Ellis Rotary Belt Screen (RBS) is designed

to use standard wastewater treatment chemicals to break oily emulsions and attach to the

solids in the wastewater. The wastewater flows through chemical reaction tanks or tube

flocculators to provide the optimum contact time and mixing energy to improve chemical

performance. The chemically treated wastewater is filtered through the rotary belt screen

leaving the oily solids on the filter belt. These solids are washed off the filter belt and squeezed

into a screw press dewatering the sludge. This system works well and fits nicely into small

areas.

Achieve Compliance with Fats, Oils, and

Greases.

unit and gravity filters through the belt. Effluent is discharged from

the bottom of the unit. Solids are fed using an auger into the screw

press for dewatering.