Rejects 99% + filterable contaminants

Recovery rates up to 80%

Tackles chemically aggressive process streams (high/low pH)

Removes emulsified and free oils

Filters fibers without plugging

Diminishes most regulated contaminants

Decreased fresh water intake cost

Lowers water heating consumption

Reduces regulated contaminants lowering POTW Surcharges

Just as life cannot sustain without clean water, neither can the laundry industry. Water is crucial for the washing processes and massive volumes are used and discharged every minute. Unfortunately, shadowing large GPD usage and toxic wastewater discharges are costs, and the high price tag attached is proving difficult for laundries to remain cost-efficient.

Today, implementing a water reclamation process into a laundry plant is no longer a consideration, but a must, in order to stay competitive. The Ellis Water Solutions line of water recovery ceramic membrane systems provide pivotal reuse technology that is proven to deliver laundries greater control over water quality while diminishing overall operating costs.

Implementing ceramic ultrafiltration membrane technology, the closed filtration systems can tackle the caustic wastewater streams that are conventional processes cannot including, high levels of TSS, oil and grease, proteins, colloids, heavy metals, and detergent laden chemicals.

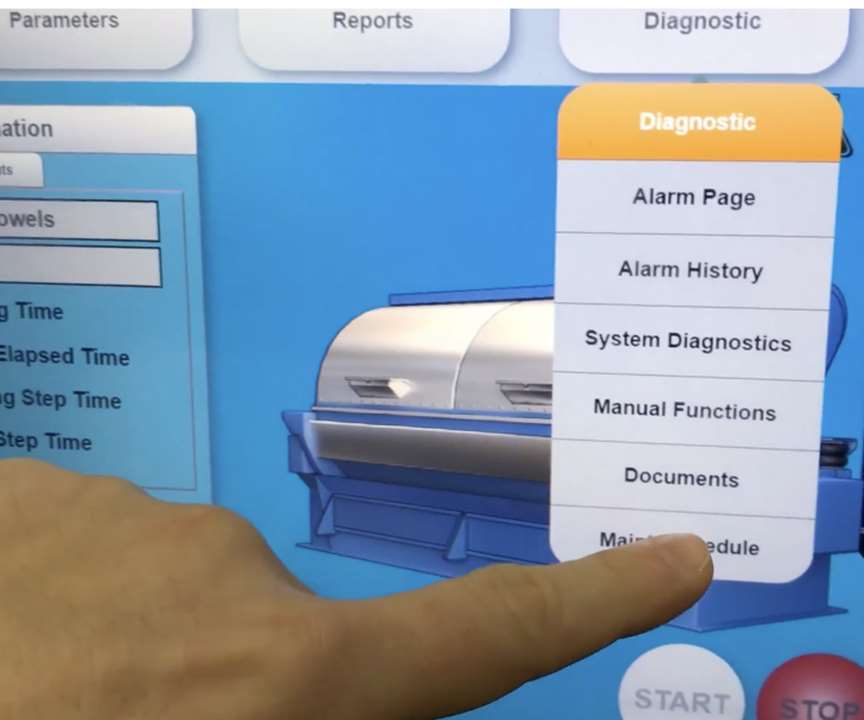

After careful assessment, each closed system is custom designed and configured, and includes a ceramic filtration skid along with the necessary pumps, tanks, piping, valves. The built-in Ellis ‘WRS’ Uptime® control interface provides a simple, user-friendly intuitive touch-screen display with pre-set maintenance schedule alerts, training videos, maintenance alarms, manuals along with schematics. Big Data collection technology allows customers to meet strategy objectives that include: operational performance optimization, streamlined and automated reporting, and ROI monitoring of asset investments.

OPTIONAL FEATURES

Ceramic Membrane Technology Benefits

- High abrasion resistant

- Chemical & thermal stability

- High-velocity cross flow

- Limited adverse fouling

- Durable, long life-cycle

- Excellent flux rates

- MF, UF, or Nano configurations

Integrated Modular Design Benefits

- Pre-engineered skid design

- Easily integrates into pre-existing treatment systems

- Flexible scalability

- Small footprint

Advanced Interface & Automation

ELLIS UPTIME INTELLIGENT MACHINE MANAGEMENT SYSTEM — A intuitive built-in proactive operator interface has pre-set maintenance schedule alerts, training videos, maintenance alarms, manuals, and schematics. AUTOMATION — Big data collection / evaluation and remote connection troubleshooting.