A polishing filter is specifically designed to remove or reduce suspended solids (20 microns or greater) by 90% via filtration. More significant solids loading and/or finer particle removal can be achieved by using alternate media beds. Special media is selected per application to achieve the highest quality effluent while sustaining low-pressure drop across the filter. There are two main types of polishing filters used in Industrial Wastewater Treatment. These include Mechanical Filters and Chemical Filters.

Polishing Filter – Mechanical Media

Mechanical media is the first phase in polishing filtration. The wastewater passes through a fine grade of media such as sand, beads, or gravel to remove large, visible particulates. Mechanical media can be dense or loose depending on what needs to be removed from the wastewater. It is the material that allows the water to flow through the media.

Polishing Filter – Chemical Media

Chemical media removes the things the wastewater effluent that are not visible but can lead to noncompliance. There are numerous chemical media that can be used to remove your pollutant of concern.

Chemical Media for Polishing Filters include:

- Activated Carbon

- Walnut Shell Media

- Ion Exchange Resin Beds

Chemical media can remove pollutants such as:

- Water Hardness

- Iron and Manganese

- Heavy Metals

- Toxic Organic Chemicals

- Petroleum Hydrocarbons

Industrial Polishing Filter – How it Works

Feed Water enters each vessel, passes through a selected media bed where suspended solids are filtered out. Filtered water leaves each vessel and continues out through the filtered water valve. The filtration process is automatic with the water feed brought to the system using a feed pump.

Captured solids are backwashed one vessel at a time per operator input, differential pressure or a timed basis. Backwash is achieved by using the filtered water from two of the vessels and diverting over to the remaining vessel. All vessels are backwashed in sequence and the filtration process continues while in the backwash cycle. An independent backwash water supply is not required.

Applications

- Industrial Process Water

- Produced Water

- Groundwater

- Cooling Water Filtration

- Dissolved Air Flotation (DAF) Effluent Polishing

- Inclined Plate Clarifier (IPC) Carryover Removal

- Industrial Return Water Polishing

- Iron Precipitate

- Pre-Carbon Treatment and

- Many, Many more applications.

Sand Wastewater Filters

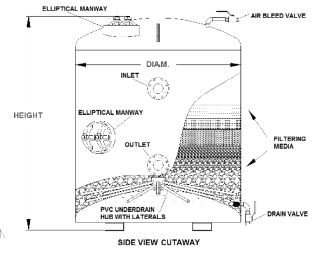

Sand filters can handle more solids and higher flow rates than bag filters. Sand filters are used mainly to remove solids from a wastewater stream that has high levels (between 250 mg/L – 10,000 mg/L) of suspended solids and sediments. Sand filters strain solids from the water treatment stream. Water is pumped into the top of a sand filter vessel. As the solids-laden water trickles through the sand, most solids of 50 µm or larger are caught in the pores between the sand. Some tiny particulates are adsorbed onto the surface of the sand. Filtered water, free of these particulates, continues through the sand.

Sand filters may include two to five pods (vessels). More pods mean a higher flow rate. Depending on the specific job, water leaving the sand filter may be discharged or may be further treated.

Over time, the sand starts to clog or become less effective at removing solids. When this happens, the filter needs servicing (backwashing or media replacement). Backwashing flushes solids from the sand bed. The backwash is captured for treatment or safe disposal. When the media is removed, the captured solids are removed with it, and can be safely disposed.

Multi-Media Filters

A multi-media filter is similar to a sand filter but may sometimes be more efficient. A multi-media filter has one or two media layers above the gravel bed. The media are ordered in decreasing porosity. Larger, lighter media stays on top and the denser, smaller media stays on the bottom. The largest particles are removed near the top of the media bed, and as particles get smaller, they are captured deeper and deeper in the media. Multi-media filters trap more particles than sand filters before needing backwashing.

Media Applications for Polishing Filters include activated carbon, water softening resins, iron and manganese removal, heavy metals removal. And trace organics and dyes.

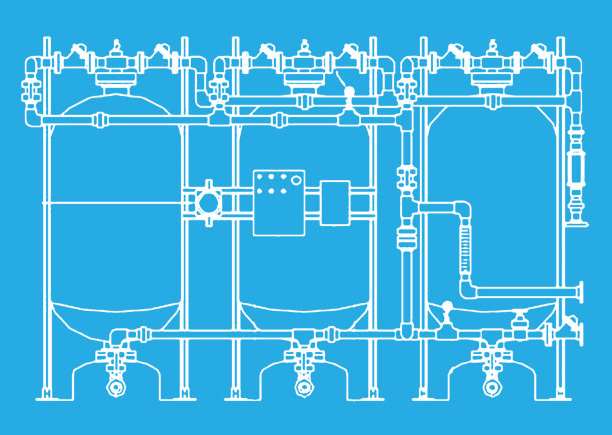

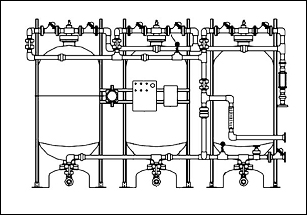

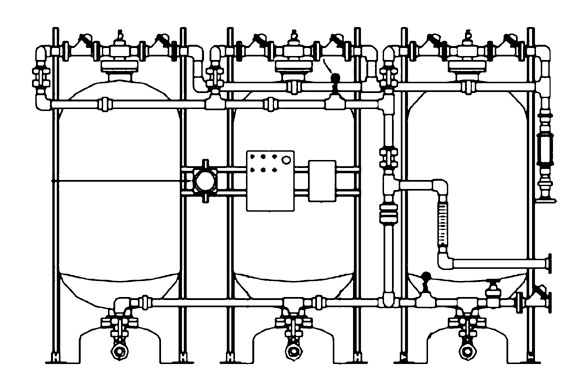

LEAVE SOLIDS BEHIND

Similar to a home filtration system, the Polishing Filter retains solids as the water flows through different filter media.

CONTINUED PERFORMANCE

The valving configuration on the Polishing Filter allows it to remain in continuous operation even while backwashing.

THREE’S COMPANY

The standard 3-vessel configuration optimizes efficiency while maintaining hydraulic throughput.

HOW IT WORKS

Feed enters each vessel, passes through a selected media bed where suspended solids are filtered out. Filtered water leaves each vessel and continues out through the filtered water valve. The filtration process is automatic with the water feed brought to the system using a feed pump.

Captured solids are backwashed one vessel at a time per operator input, differential pressure or a timed basis. Backwash is achieved by using the filtered water from two of the vessels and diverting over to the remaining vessel. All vessels are backwashed in sequence and the filtration process continues while in the backwash cycle. An independent backwash water supply is not required.