On the Edge, The Ellis Belt Filter Press Dewatering (BFD) System may be able to get you in compliance at a lower cost than traditional wastewater treatment systems. If you are at your discharge limitation and do not have enough space for a full-scale wastewater system, the belt filter dewatering system could bring you into compliance.

- Up to 32% Total Suspended Solids removal

- Up to 43% Fats, Oils, and Grease removal

- Filters Fibers without plugging

- Solids Dewatered Before Disposal

- Predictive Analytics

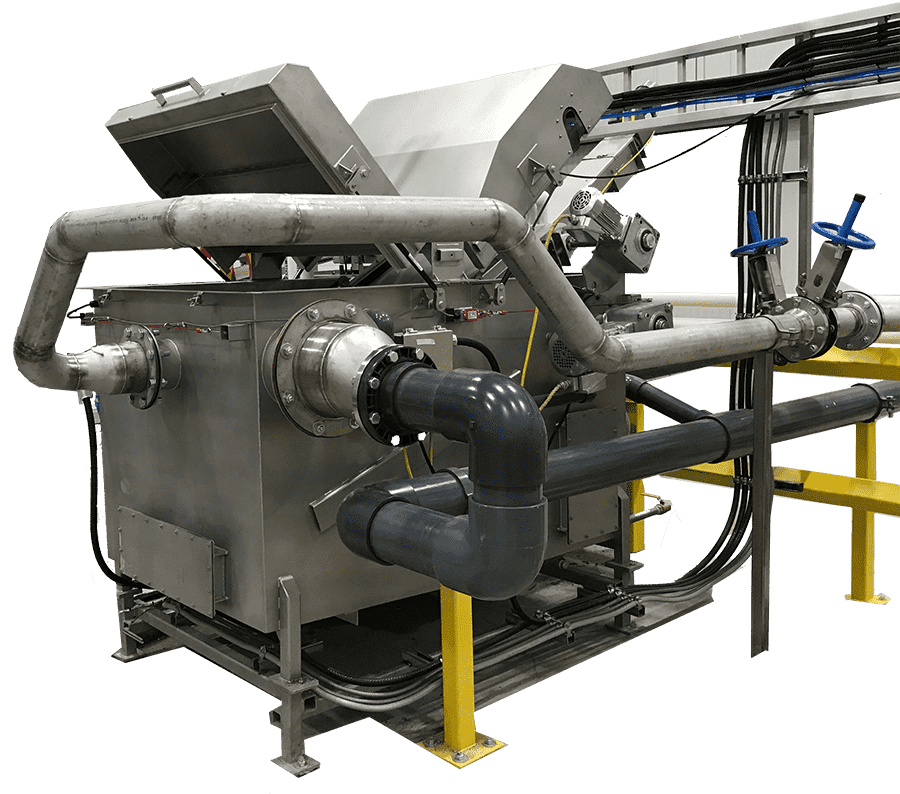

HOW THE BELT FILTER PRESS DEWATERING SYSTEM WORKS

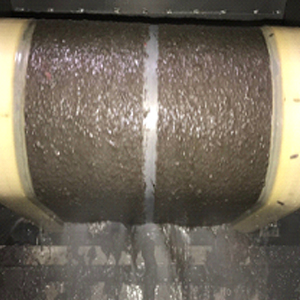

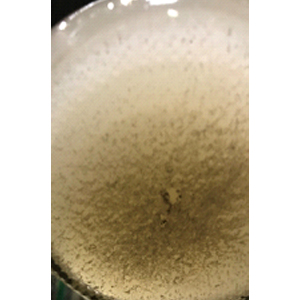

The Belt Filter Press Dewatering System utilizes a continuously rotating filter belt to separate solids from the influent ideal for sludge detwatering. The Belt Filter Press Dewatering System is effective with a wide variety of wastestreams with screen openings between 65 and 300 microns. The continuous belt screen receives influent wastewater in an enclosed tank, which is then filtered as the filter belt comes out of the water tank. The solids residue is then conveyed above the tank liquid level, to a belt cleaning section and then removed by water spray and dewatered using a screw auger. The dewatered solids or cake can discharge to a container or to a conveying system to a solids disposal container for easy disposal.

This wastewater filtering technology can also be used with wastewater treatment chemicals such as coagulants and/or flocculants to break oily emulsions found in the wastewater. Oils and Greases, Heavy Metals, Heavy Solids, and Insoluble BOD and COD concentrations can be reduced from the wastewater discharge.

Unlike a vibratory shaker screen that can blind with varying wastewater solids, the Belt Filter Dewatering System utilizes a water spraying system to keep the filter media clean and prevents blinding. This feature minimizes the time spent by a maintenance operator required to keep the technology functioning.

Performance Data

Total Suspended Solids (TSS) removal from Belt Filter Dewatering (System)

| Influent (mg/L) | Effluent (mg/L) | % Removal |

| 2,844 | 2,392 | 15.9% |

| 4,483 | 3,500 | 21.9% |

| 4,600 | 3,596 | 21.8% |

| 2,204 | 1,804 | 18.1% |

| 3,392 | 2,308 | 32.0% |

| 2,520 | 1,856 | 26.3% |

| 1,370 | 960 | 29.9% |

| 1,340 | 1,360 | 0% |

| 1,653 | 1,520 | 8.6% |

| 1,756 | 1,556 | 11.4% |

| 1,972 | 1,968 | 0.2% |

| 4,244 | 3,068 | 27.7% |

| Average 2,624 | 2,092 | 20.0% |

| Minimum 1,340 | 960 | 0% |

| Maximum 4,600 | 3,596 | 32.0% |

Fats, Oils, and Grease (FOG) Removal from Belt Filter Dewatering System

| Sample # | Influent | Effluent | % Reduction | Pretreatment | Chemical Reaction |

| 1 | 386 mg/L | 334 mg/L | 13.4% | No Treatment | None |

| 2 | 853 mg/L | 135 mg/L | 86.1% | No Treatment | None |

| 3 | 1,420 mg/L | 135 mg/L | 90.0% | No Treatment | None |

| 4 | 169 mg/L | 109 mg/L | 36.0% | No Treatment | None |

| 5 | 391 mg/L | 274 mg/L | 29.9% | Flocculant Addition | Feed Pipe |

| 6 | 522 mg/L | 307 mg/L | 42.1% | Flocculant Addition | Feed Pipe |

| 7 | 453 mg/L | 333 mg/L | 27.0% | Flocculant Addition | Feed Pipe |

| 8 | 131 mg/L | 90 mg/L | 31.0% | Flocculant Addition | Feed Pipe |

| 9 | 391 mg/L | 161 mg/L | 60.0% | Flocculant Addition | Feed Pipe |

| 10 | 443 mg/L | 275 mg/L | 37.9% | Flocculant Addition | Feed Pipe |

| 11 | 312 mg/L | 122 mg/L | 60.9% | 2X Flocculant Addition | Feed Pipe |

| 12 | 293 mg/L | 204 mg/L | 30.3% | 2X Flocculant Addition | Feed Pipe |

| 13 | 453 mg/L | 310 mg/L | 31.6% | Flocculant Addition | Tube Flocculator |

| 14 | 391 mg/L | 360 mg/L | 31.0% | Flocculant Addition | Tube Flocculator |

| Avg Reduction | 43.3% |

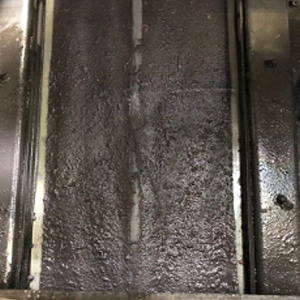

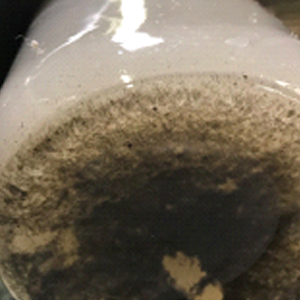

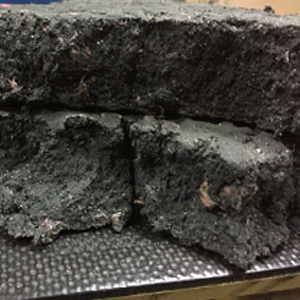

Look at the Oil and Grease Removal from the Wastewater – The Fats, Oils, and Greases go out the door to the land fill

Oil and Grease Concentrations found in Lint/Solids Discharged from the Belt Filter Dewatering System.

| Sample # | Time | Oil and Grease | Description |

| Day 1 | 9:00 AM | 33,400 mg/Kg | Slimy, Black, Oily |

| 11:00 AM | 38,900 mg/Kg | Slimy, Black, Oily | |

| 1:30 PM | 46,400 mg/Kg | Slimy, Black, Oily | |

| 3:30 PM | 12,500 mg/Kg | Dry Lint | |

| Day 2 | 9:00 AM | 400 mg/Kg | Dry Lint |

| 11:00 AM | 63,810 mg/Kg | Slimy, Black, Oily | |

| Day 3 | 9:00 AM | 82,200 mg/Kg | Slimy, Black, Oily |

| 11:00 AM | 100,000 mg/Kg | Slimy, Black, Oily | |

| 2:00 PM | 64,700 mg/Kg | Slimy, Black, Oily | |

| Day 4 | 11:45 AM | 102,000 mg/Kg | Slimy, Black, Oily |

| Day 5 | 9:10 AM | 109,000 mg/Kg | Slimy, Black, Oily |

| 9:30 AM | 65,700 mg/Kg | Slimy, Black, Oily | |

| 1:30 PM | 2,810 mg/Kg | Dry Lint | |

| 1:50 PM | 66,400 mg/Kg | Slimy, Black, Oily |