Immediate results for less floor space

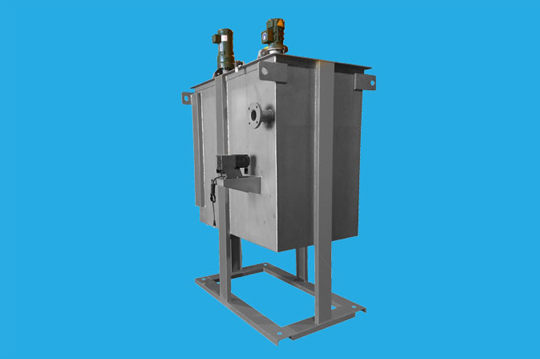

pH Conditioning System

pH Conditioning System

SHOOT FOR STABILIZATION

Custom designed catwalks, guardrails, and ladders will deliver a safe and functional pH Conditioning System that minimizes maintenance and time associated with monitoring your treatment process.

SET THE PACE

Ellis pH Conditioning Systems are readily integrated with control systems to monitor liquid level and pH. VFD drives can also be incorporated to adjust the speed for control systems such as dosing pumps and mixers.

MIX THINGS UP A BIT

pH Conditioning Systems are sized to deliver the optimal mixing time with conditioning chemicals to reduce the potential for overdosing and lead to direct savings.

Chemical conditioning needs vary for every application. However, there is one underlying fact that is true for all treatment processes; proper conditioning can and will save money and yield positive benefits on the overall treatment process.

A pH Conditioning System allows for more contact time and the ability to see the results of chemical addition immediately. It is generally used when floor space is available and routine inspection of the chemical reaction is necessary.

Applications

- Algae Removal

- Animal Food Production

- Dairy & Mil Byproducts

- Dyeing & Finishing Textiles

- Energy Production Byproducts Treatment & Conditioning

- Food Packaging & Processing Byproducts

- Frozen Food Processing

- Groundwater Remediation

- Heavy Metal Removal

- Industrial & Commercial Laundries

- Industrial Floor Wash-down Solids Separation and Conditioning

- Juice Separation and Conditioning

- Meat Packing & Processing Byproducts

- Oil & Petrochemical Production

- Pre-biologic Pressing Treatment/ConditioningTreatment/Conditioning

- Preparation of Parts for Painting

- Pulp & Paper Production

- Secondary Biological Solids Removal

- Secondary Sludge Thickening (Industrial & Municipal)

- Steel Mill Production

- Storm Water Runoff

- Vehicle & Fleet Washing

OPTIONAL FEATURES

Materials of Construction

The Ellis pH Conditioning System is available in A-36 carbon steel, 304 stainless steel (SS), 316 SS. Retrofits are also available upon request. Liners and internal wear protection are also available. These can minimize the adverse effects often associated with corrosive and/or abrasive materials handling.

Intake & Discharge Pumping

Pumping systems for all pH Conditioning Systems are available. Ellis will furnish the ideal pump suitable for the liquid (centrifugal, progressive cavity, etc.).

Maintenance & Inspection Hatches

Hatches are available in a wide variety of sizes and shapes to best satisfy the maintenance and inspection needs of clients. Hatches can be installed in any non-structural portion of the pH Conditioning System. Discharge ports for periodic material sampling can also be incorporated into any design.

Covers

All sysstems can be furnished with or without covers. Vapor retaining covers can be hinged to simplify maintenance.

Mixing

Maintaining suspension in liquids can be vital for further treatment and/or proper conditioning. pH Conditioning Systems can be equipped with either recirculating pumps or paddle mixing systems. Mixing systems can also be incorporated with variable frequency drive (VFD) controls for adjustment of mixing speeds.

OSHA Safety Guards & Catwalks

Access for inspection of large systems is a common requirement for systems. Ellis has designed and installed hundreds of ladders and catwalk configurations to best satisfy customer safety and maintenance needs.

Freeze Protection

Some clients choose to locate pH Conditioning Systems in an outdoor location. While this is perfectly acceptable it can be problematic in particularly colder Northern climates. Ellis offers a complete line of heating systems. Even in warmer climates where freeze-thaw is not common it is never a bad idea to prevent issues with the addition of internal heating systems and/or an insulated liner.

Controls

pH Conditioning Systems are readily equipped with most monitoring controls. Liquid level and pH monitoring controls are standard available options. VFD drives can also be incorporated to adjust the speed for control systems such as dosing pumps and mixers. Explosion proof controls are also available for all systems. Please contact an Ellis Sales Representative for any custom control requests.