Having separation anxiety over poor performance with your oil water separator? Take a look at these tips to try and get your oil water separator effluent back into compliance.

Some of the variables that can negatively impact the performance of your oil water separator include the following:

- Improper System Design – Is the flow rate too high? Is the oil concentration too high for the system?

- Poor System Maintenance – How often are you cleaning your oil water separator?

- Emulsifying Agents – Any changes to the wastewater? Have there been changes in cleaning compounds in the process that may include emulsifiers?

- Solids Build Up – Many process oils may pick up solids? These solids will settle and could plug the coalescing material or bottom drain.

Simple Tips for Fixing Problems and General Maintenance

- The Unit should be inspected monthly.

- Make sure to keep records of your inspections and maintenance activities.

- Oils and sediment should be removed and properly disposed of (not in the trash).

- Cleaning and proper disposal of sediment and oils can be done by most environmental contractors. Be sure to keep copies of the disposal records.

- An oil water separator needs to be properly and regularly maintained to stay in good working order. They must be cleaned on a routine basis.

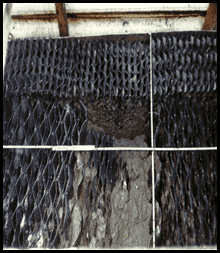

- Dirt and heavy oil may build up on the coalescing media packs, reducing the unit’s efficiency which can cause the levels of oil in the treated wastewater to exceed the effluent discharge limits.

Media Pack

When these OWS units are not drained and cleaned out regularly, oils and other debris will plug

the coalescing packing material and make them useless.

Cleaning the Oil Water Separator

• Maintenance should be carried out regularly by a staff familiar with the system

operation.

• Keep inspection and maintenance logs and have them available for ready reference.

• The strength of the waste stream, (oil and grease loadings as well as TSS loadings) will

determine the frequency of the cleaning and maintenance.

• The OWS unit should be drained, cleaned, and inspected annually at a minimum.

Cleaning Procedures

• Turn off the influent water flow to the unit.

• Open the unit cover.

• Remove oil for proper disposal or recovery.

• Drain the water from the separator and return to the wastewater holding or storage tank.

• Measure the depth of the residual solids and record the level in a logbook. This will

serve as a reference for scheduling future maintenance and system cleaning.

• If excessive solids are present, dispose of the solids and increase the frequency of

inspections and cleanings.

• After draining the unit, inspect the coalescing media packs to determine if cleaning is

required. These can be cleaned while still in the unit or removed for cleaning.

• To clean the coalescing packs without removal, use a low-pressure hose (40-70 psi) in

between the plate spaces on the media plate packs. Any dirt flushed from the plates

should be removed through the drain on the tank outlet.

For cleaning the coalescing packs outside of the oil water separator, carefully remove them from the separation chamber. Use the lugs when lifting the coalescing packs. Wash the coalescing packs down with a low-pressure (40-70 psi) hose while taking extreme care to avoid getting the discharge

on the ground where it has access to groundwater. All that needs to be removed

is the sludge buildup. DO NOT scrub the coalescing packs. An oil layer on the media packs attracts other oils

Contact our Water Solutions Team to assist you with any of you separation needs!